Specifications

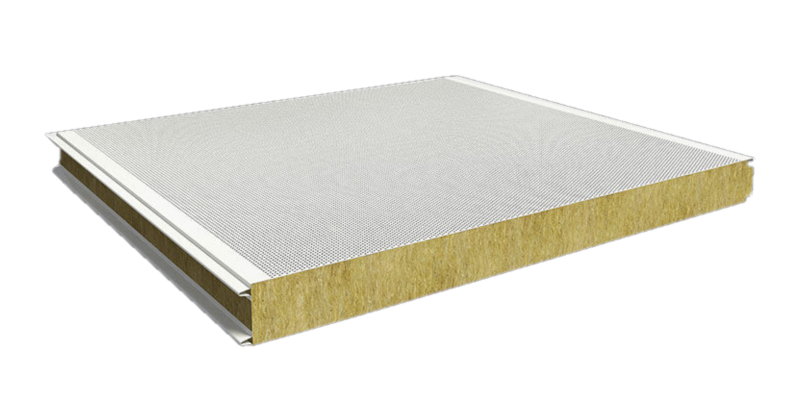

| CHARECTERISTICS | SPECIFICATION |

|---|---|

| Panel Sizes | 3960 x 500, 2960 x 500, 2460 x 500, 1960 x 500 mm |

| Panel Thickness | 80mm | 100 mm | 120 mm |

| Wind Load | Designed as per IS 875 Part-III, 1987 |

| Sound Proofing | Class -A4 |

| Sound Deadening | Class -B2 |

| Type of Wall | Double skin insulated wall |

| Facing Sheet | Plain metal sheet / GI sheet/Aluminium , 0.5 to 1.2 mm thick |

| Backside Sheet | Perforated sheet/ GI sheet/Aluminium with 22-46 % open area |

| Infill / Core | Rock wool Confirming to IS-8183 & BS 476 of varies density and Thickness. Rock Wool covered with Fiber tissue paper fire-resistive. |

| Cover | Water repellent tissue paper for infill material lamination,50-micron thickness |

| Sound Damping | High density mass loaded vinyl barrier of 2 MM thickness |

| Joint | Each panel having a tongue & groove to join perfectly with each other |

| Gasket | The panel and structure having neoprene rubber gaskets at the joint to block noise leakage. |

| Vertical Post/ Structure | The structure is of ‘H’ profile in which acoustic panel slides longitudinally. |

| Finish | All metallic surface/parts are galvanized / powder coated / painted in desire shade. |

Advantages

- Eliminating Residual Sound

- Improving Sound Intelligibility

- Acting as Absorbers and Diffusers

- Absorbing Unwanted Sounds

- Improving Wall Aesthetics

- Absorbing Surface Frequencies

- Fire resistance

Applications

- Offices/Work Spaces

- Conference Halls

- Auditoriums

- Theaters

- Churches/Church Halls

- Libraries

- Restaurants

- Hospitals

- Recording Studios

- Broadcasting Studios

- Film & Television Production

- Control Rooms

- Assisted Living Facilities

- Food Processing Plants

- Manufacturing Facilities