Materials Used

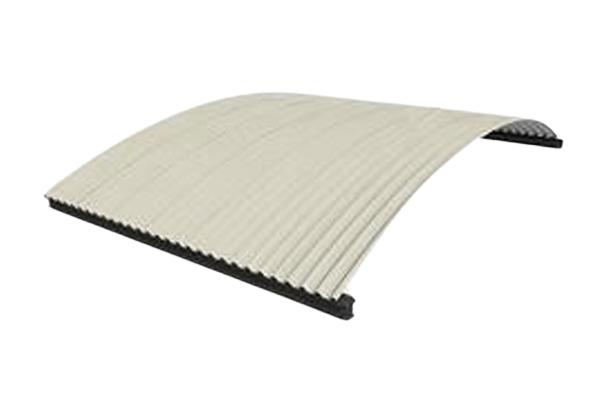

- Color coated steel structural grade in coil form.

- Steel grade 300 mpa YS min.

- Steel thickness from 0.85mm to 1.6mm TCT( Total coating thickness).

- As per ASTN A 792/A755 steel sheet/Aluminum-Zinc alloy.

- Hot dipped galvanized or galvalume materials were used.

- Galvanized- 120 gsm or Galvalume AZ 150 as per customer specification.

- Coil width 914mm,sheet width 610mmwith tolerance of thickness + or – 0.03mm.

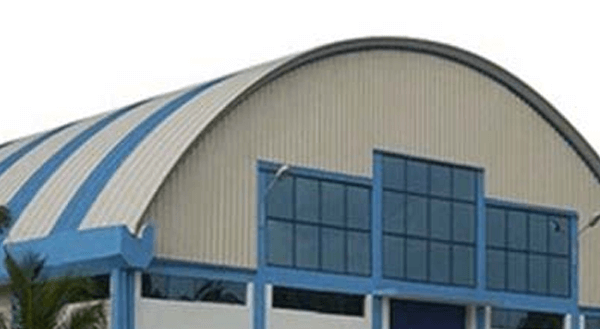

Roofing Designs

- Curved designs as per client requirements.

- Roofing can be done over the RCC structure which is the commonly used one as per customer’s design and requirements.

- Roofing can also be done over steel structures.

- Elevated base, L-section roofs, Half arch, Multiple bays, Differential heights structures, Ground to ground ( as per below drawings).

Advantages

- Self-supported roofing is manufactured from color-coated galvalume/bare galvalume/color-coated galvanized coils of thickness from 0.85mm TCT to 1.6mm TCT.

- They are self-supporting roofs and do not require any trusses, purlins, or any ancillary supports.

- High standard of thermal insulation

- It is a 100% leakproof roof with zero maintenance and is free from holes, nuts, and bolts.

- The roof has a clear span that can accommodate larger enclosed volumes and is resistant to damage and corrosion.

- It is very aesthetically appealing and maintains a cool temperature.

- Birds cannot nest under the truss-less roofs.

- On-site installation of approximately 10000 sqft in just 12 hours.

- The roof is sturdy and durable ensuring long life of 25 to 30 years.

- Truss less roofing is preferred because of the clear span of up to 35 meters.

Applications

- Warehousing

- Logistic companies

- Automobile service centers

- Food processing, manufacturing

- Textiles

- Defense structures

- Aircraft hangers

- Auditoriums

- Exhibition halls

- Conventional centers