Structural Sub Systems

Alfa uses standard components and designs to manufacture a wide range of structural subsystems according to customers' requirements. These structural subsystems fulfill the requirements of two types viz. Aesthetic and Functional. Alfa produces a large number of structural subsystems according to exact specifications as the strength of the pre-engineered building system depends largely on various incorporated structural subsystems. Subsystems are available for the following structures.

- Endwall Roof Extension

- Sidewall Roof Extension

- Transverse Partition

- Longitudinal Partition

Some structural subsystems offered by Alfa are

- Canopy

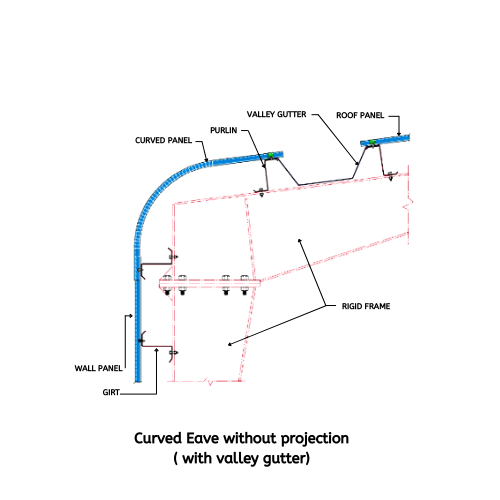

- Curved Eave with projection (without valley gutter)

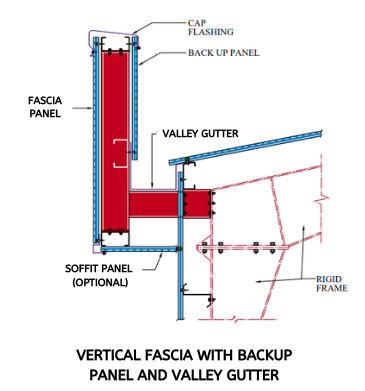

Vertical fascia with back up panel and valley gutter

- Center Curved fascia

- Standard Roof Monitor

Advantages

| Reduction in project cost | Cost savings primarily result from time savings on the Project. This also results in the earlier realization of revenue to the owner on a commercial project |

|---|---|

| Saving in construction time | About 30-50% time-saving in total project schedule due to fast delivery and quick site erection. |

| Low Maintenance | High-quality paint systems are available for steel and cladding to be provided along with maintenance-free service life |

| Large clear spans | Buildings can be supplied in clear spans up to 60 meters, particularly suitable for aircraft hangers, sports facilities, etc. |

| Flexibility in expansion | Buildings can be designed for future expansion in length, width, and height. |

| Peb vs Conventional | Buildings are supplied with roof and wall insulation to reduce energy costs and improve comfort level inside the building |

| Superior quality | Complete manufacturing is done in our plant as per ISO quality assurance standards |

|

|

Peb vs Conventional

| PEB Buildings | Conventional Building |

|---|---|

| Higher resistance to seismic forces due to low weight flexible frames | Special aesthetic design required |

| Reduced time because of international design standards & codes using standard sections and connections | Increased design time due to start from scratch and availability of less design aids |

| Higher resistance to seismic forces due to low weight flexible frames | Rigid heavy weight structures not suitable for seismic zones |

| 30% less PEB steel structures weight through efficient use of steel | High weight due to excessive safety factor and the usage of heavier steel sections |

| Factory controlled quality | Every project to be fabricated at site |

| Low initial cost of peb steel buildings(cost per square meter about 30% less than the conventional) and faster delivery | Special design and features developed for each project at higher costs |

| Simple Foundation, easy to construct and light weight PEB structures | Extensive heavy foundation |

| Average delivery time 6-8 weeks | Average delivery time 22-28 weeks |

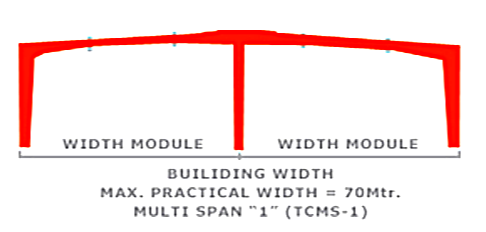

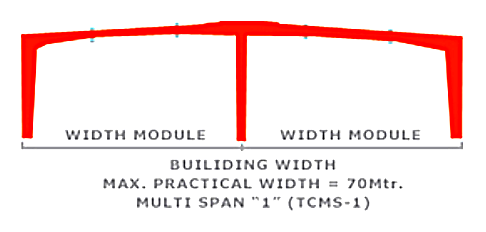

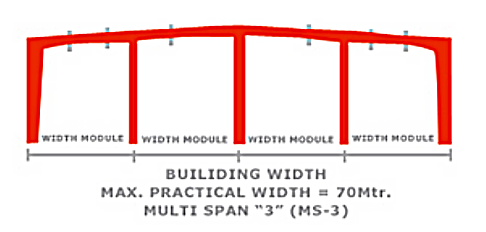

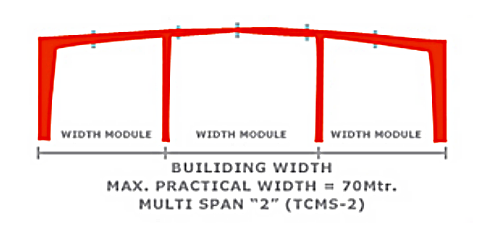

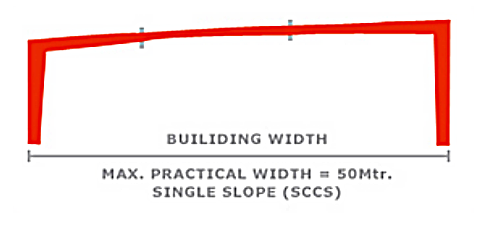

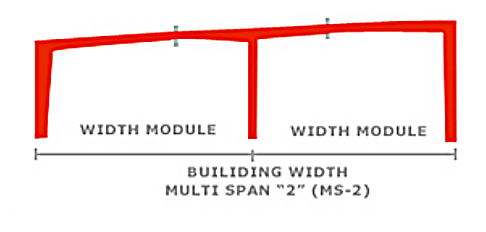

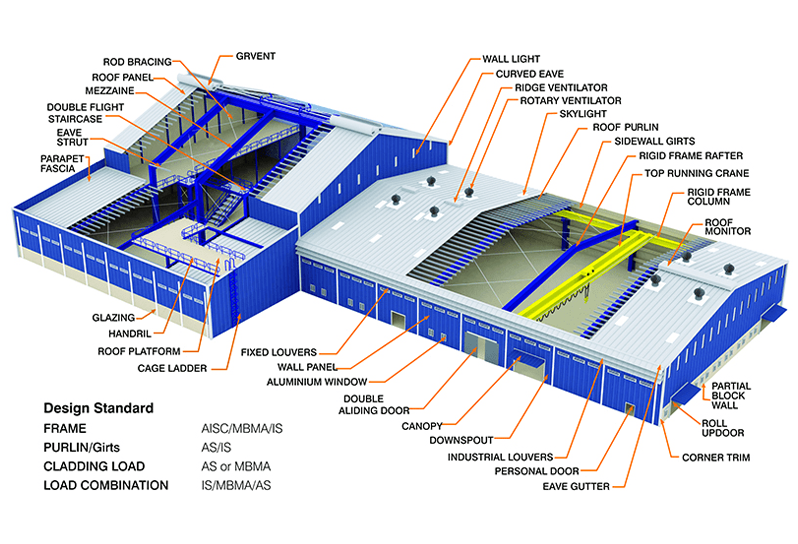

Primary Steel Framing

ALFA Steel Building Solutions pre-engineered building manufacturers in Bangalore are custom-designed to meet your exact requirements. Each is designed by professional, experienced engineers and manufactured to exact tolerances under rigid quality-controlled plant conditions. The steel plates are painted with a minimum of 25 Microns DFT of red oxide primer. Each steel structural framing system is designed by experienced engineers and manufactured to precision tolerances under rigid quality-controlled plant conditions. Some common primary steel structural framing systems include

.png)

.png)

.png)