Manufacturing Process

The top and bottom coil (sheet metal) are clamped onto the plants unwinding unit and fed into the machine. In the first step, “corona system” cleans both reverse sides of the sheet metal using high frequency to remove greases and dirt and to guarantee the best possible subsequent full spread adhesion between foam and sheet metal. Thereafter the protective films are rolled onto outside of both metal sheets. The sheets are then brought together, the bottom sheet is foamed by the swinging foam head and the top sheet is mechanically steadied. Immediately thereafter, the panel is fed continuous line into the heated drying tunnel where the foam expands to its full volume, binds to the sheets and transforms both sheets to one robust, shear resistant composite structural panel. After leaving the tunnel the panels are cut according to your specification using flying saw/cutter.

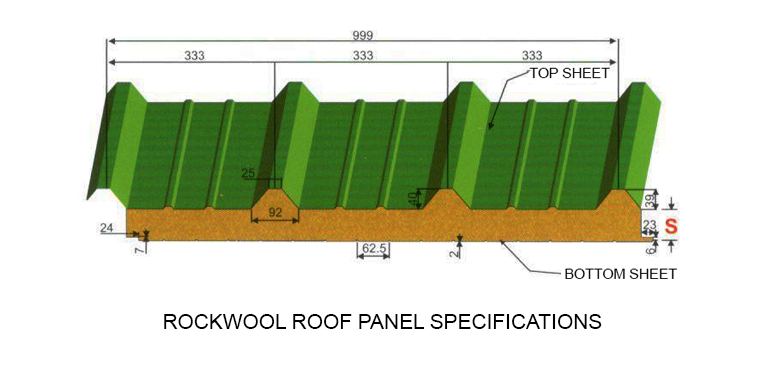

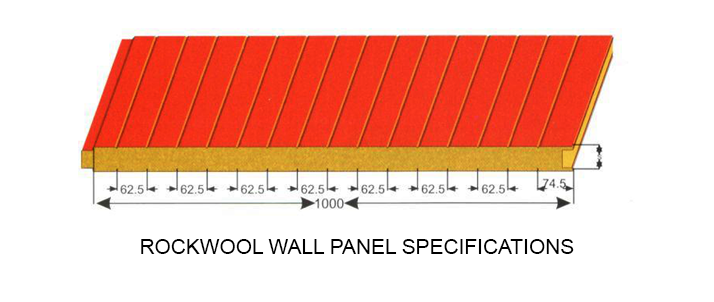

Specifications

| Thermal performance and strength | At 250C mean temperature thermal conductivity varies between 0.031W/mk and 0.036W.mk depending upon the density of the material. |

| Acoustic PerformancePanel length available | Alfa panels offer excellent sound absorption. The Noise reduction Coefficient (NRC) range from 0.80 to 0.95. |

| Fire Performance | Alfa panels do not contribute in any way to the spreading of fire. It does not shrink, stretch or deform when exposed to fire. It does not cause smoke or any burning droplets in case of fire. It significantly contributes to improved fire safety. |

| Resistance to moisture | Water absorption by partial immersion: 0.5kg/m2. Water absorption by full immersion: 10% to 11.5% of weight (tests done as per BS2972) |

| Storage | To store for long duration, Alfa panels should be stored indoor. If stored outside, the panels should be stacked clear of ground and covered with a securely anchored weather proof sheet. The panels should not be left exposed to weather. |

| Non Toxic | Alfa panels are not hazardous to health and do not contain asbestos. |

| Environmental impact | Alfa panels are free from CFCs, HFCs and HCFs and contain phenol resins within the permissible limits. |

Advantages

- Fire Retardant

- Excellent and durable thermal insulation.

- Great energy saver.

- Easier installation in hostile weather conditions.

- Easy repair and replacement in case of damage.

- Long life and very low maintenance cost

- Good sound insulation

- Various designs.vivid colours.

- Easy Applications.

- High load bearing capacity at low weight.

- Capacity for rapid erection without lifting equipments.

- Hidden self tapping screws for aesthetic appeal.

- Reasonable fire reaction and resistance

- Fast and easy installation.

- Light weight.

- Energy conservation as per ECBC code.

- Space saving.

- Cost Savings

Applications

- Industrial Buildings.

- Partitions-Semi Glazed.

- Malls/Departmental Stores.

- Poultry Form.

- Warehouse/Godown.

- Farm House.

- Cold storage/Blast Freezers.

- Pharmaceutical Manufacturing units.

- Air Handling Units.

- Commercial Buildings.

- Dairy industry.