Manufacturing Process

The top and bottom coil (sheet metal) are clamped onto the plants unwinding unit and fed into the machine. In the first step, “corona system” cleans both reverse sides of the sheet metal using high frequency to remove greases and dirt and to guarantee the best possible subsequent full spread adhesion between foam and sheet metal. Thereafter the protective films are rolled onto outside of both metal sheets. The sheets are then brought together, the bottom sheet is foamed by the swinging foam head and the top sheet is mechanically steadied. Immediately after that, the panel is fed into the heated drying tunnel where the foam expands to its full volume, binds to the sheets and transforms both sheets to one robust, shear resistant composite structural panel. After leaving the tunnel the panels are cut according to your specification using flying saw/cutter.

Specifications

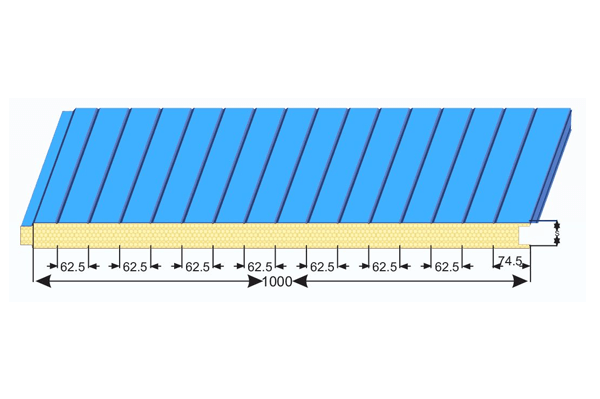

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

| Panel width available | 1000mm |

| Panel length available | 2000mm-12000mm |

| Average density | 40± 2kg/m |

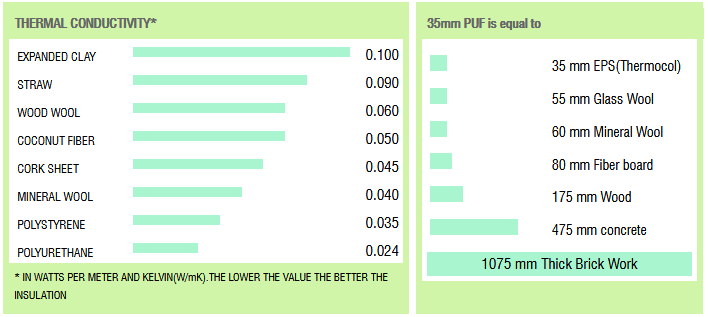

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| Free from CFC | CFC free |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Cubic Area Change | =1%(-30 C – 100 C/96h) |

| Finish | Ribbed, Micro Ribbed, Plain Ribbed |

| Polyester primer | 5 micron Non-toxic food-graded STANDARD polyester finish paint. |

| RAL 9010 color | : 20 micron |

| Back coat | 5 micron |

| Resistance to saline mist | 5 micron |

| 500h (ECCA TB) | 100 h (ASTM D 2247) |

Advantages

- Tongue and groove type joinery system.

- Hidden self tapping screws for aesthetic appeal.

- Great energy saver

- Fast and easy installation

- Light weight

- Space saving

- Various designs.vivid colours.

- Energy conservation as per ECBC code.

- High load bearing capacity at low weight.

- Excellent and durable thermal insulation.

- capacity for rapid erection without lifting equipments.Easier installation in hostile weather conditions.

- Easy repair and replacement in case of damage.

- Long life and very low maintenance cost

- Good sound insulation

- Reasonable fire reaction and resistance

Applications

- Industrial Buildings.

- Partitions-Semi Glazed.

- Commercial Buildings.

- Warehouse/Godown.

- Cold storage/Blast Freezers.

- Farm House.

- Pharmaceutical Manufacturing units.

- Air Handling Units.

- Poultry Form.

- Dairy industry.

- Malls/Departmental Stores.

Energy Efficiency

with 80 mm thick sandwich panels with polyurethane rigid foam, the U value is 0.297 W/(m K).In comparison,

asolid wall with 24 cm thick masonry and 2 cm plaster walls has a U value of 1.85 W/(m K).

Rigid polyurethane foam combines excellent thermal insulation properties with good mechanical strength,making it an outstanding construction material that does not rot,mold-resistant,odorless and non-toxic for all conceivable applications,The foam is resistant to the chemicals typically used in construction and is compatible with most solvent-containing adhesives,paints and wood preservatives.

Polyurethane rigid foam is extremely durable and can be installed easily and securely,ensuring cost-effective,efficient construction.