Specifications

| Panel thickness available | 30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

| Panel width available | 1060mm |

| Panel length available | 2000mm-12000mm |

| Average density | 40± 2kg/m |

| Thermal conductivity | 0.024-0.03 W/m |

| Temperature range | -40+800C |

| Free from CFC | CFC free |

| Type of foam | B1, B2, B3, PIR |

| Heat transfer co-efficient | -0.022W/M2*k |

| Pressure | 0.10Mpa |

| Cubic Area Change | =1%(-30 C – 100 C/96h) |

Advantages

- Fire Retardant

- Hidden self tapping screws for aesthetic appeal

- Great energy saver

- Fast and easy installation

- Light weight

- Space saving

- Various designs.vivid colours.

- Energy conservation as per ECBC code

- High load bearing capacity at low weight.

- Excellent and durable thermal insulation.

- capacity for rapid erection without lifting equipments.

- Easier installation in hostile weather conditions.

- Easy repair and replacement in case of damage.

- Long life and very low maintenance cost

- Good sound insulation

- Reasonable fire reaction and resistance

Applications

- Industrial Buildings.

- Partitions-Semi Glazed.

- Commercial Buildings.

- Warehouse/Godown.

- Cold storage/Blast Freezers.

- Farm House.

- Pharmaceutical Manufacturing units.

- Air Handling Units.

- Poultry Form.

- Dairy industry.

- Malls/Departmental Stores.

Foam Characteristics

| SL.No | FOAM CHARACTERISTICS | UNIT | SPECIFICATION | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 11 | TOTAL FOAM DENSITY | Kg/m3 | 48+2 | |||||||

| 12 | CORE FOAM DENSITY | Kg/m3 | 44+2 | |||||||

| 13 | COMPRESSIVE STRESS AT10% DEFORMATION | kpa | >100 | |||||||

| 14 | YOUNG COMPRESSION MODULES | kpa | >2500 | |||||||

| 15 | FOAM TENSILE STRENGTH(ADHESION) | kpa | >100 | |||||||

| 16 | YOUNG TENSILE MODULE | kpa | >2500 | |||||||

| 17 | SHEAR STRENGTH | kpa/td> | >90 | |||||||

| 18 | THERMAL-CONDUCTIVITY-A@50C MEAN TEMP & B.@10C MEAN TEMP-MAX | kpa | A.0.03 &b.0.023 | |||||||

| 19 | HORIZANTAL BURNING TEST | mm | <25 | |||||||

| 20 | HOT DIMENSIONAL STABILITY AT 85+2C/100+2C FOR 24HRS-MAX | % | LENGH+2 | |||||||

| % | WIDTH+2 | |||||||||

| % | THICKNESS+2 | |||||||||

| 21 | COLD DIMENSIONAL STABILITY AT -25+2C FOR 24HRS-MAX | % | LENGH+2 | |||||||

| % | WIDTH+2 | |||||||||

| % | THICKNESS+2 | |||||||||

| 22 | WATER VAPOR TRANSMISION-Max | ng/pasm | 8.5 | |||||||

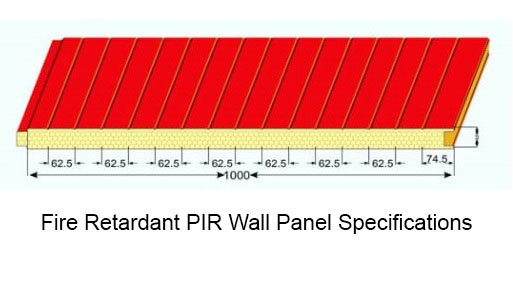

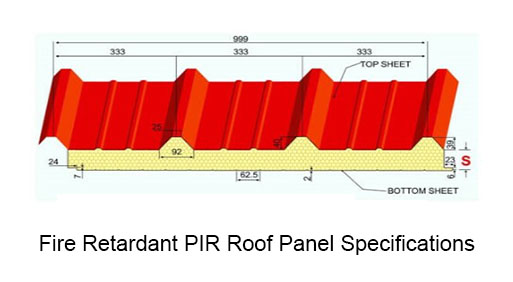

| 23 | PANEL WIDTH ROOF | mm | 1060MM | |||||||

| 24 | PANEL WIDTH WALL | mm | 1160 | |||||||

| 25 | REFERENCE PROFILE DRAWING | |||||||||

| 26 | ROOF PANEL PROFILE | |||||||||

| 27 | WALL PANEL PROFILE | |||||||||

| 28 | HIDDEN WALL PANEL PROFILE | |||||||||

Difference B/W PU PIR Panels

| SL.No | PU PANEL | PIR PANEL |

|---|---|---|

| 1 | Foaming density 40 KG/M3 | Foaming density is greater than 40 KG/M3 |

| 2 | Moderate fire resistance | High fire resistance |

| 3 | Lower ISO index > 150 | Higher ISO index > 180 |

| 4 | High smoke generation | Very low smoke generation |

| 5 | Thermal stability < 80 Degc | Better thermal stability < 120 Degc |