Flooring Choices

Floors completed and decked used as a safe working platform for subsequent installation of steelwork. For this reason, the higher floor in a group of floors(usually three-floor levels) is often concreted first. Steel framed office buildings built for offices and commercial establishments most commonly use the following flooring choices. Below are the generic forms of flooring systems most commonly used in steel-framed office buildings.

- Using steel deck profiles typically of 50 to 75 mm depth.

- The slab depth is usually 100 to 160 mm, depending on the deck depth and fire insulation requirement.

- Typical spans are 1m to 3m depending on the deck spanning capabilities.

Shallow Composite Slabs

Facade / Wall / Cladding

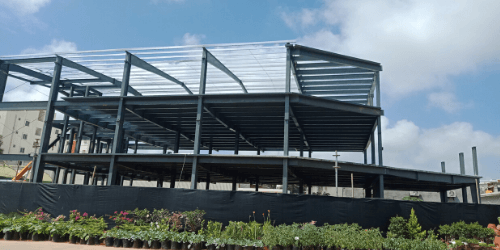

The types of facade systems used depend upon the scale of the building and its location. For premium, city center projects, curtain walling systems are generally used and these systems assist in providing internal climatic control. Separating walls are often in the form of double-skin light steel walls and steel-framed construction. These walls should be aligned with beams. In smaller projects, more traditional cladding systems are generally used, which would include brickwork and stone veneer panels. Light steel infill walls are often used to support the cladding.

Advantages

| Reduction in project cost | Cost savings primarily result from time savings on the Project. This also results in the earlier realization of revenue to the owner on a commercial project |

|---|---|

| Saving in construction time | About 30-50% time-saving in total project schedule due to fast delivery and quick site erection. |

| Low Maintenance | High-quality paint systems are available for steel and cladding to be provided along with maintenance-free service life |

| Large clear spans | Buildings can be supplied in clear spans up to 60 meters, particularly suitable for aircraft hangers, sports facilities, etc. |

| Flexibility in expansion | Buildings can be designed for future expansion in length, width, and height. |

| Peb vs Conventional | Buildings are supplied with roof and wall insulation to reduce energy costs and improve comfort level inside the building |

| Superior quality | Complete manufacturing is done in our plant as per ISO quality assurance standards |

Applications

- aircraft hangers

- Industrial parks

- Warehouses

- Factories and plant

- Metro stations

- Multistorey parking

- Industrial parks