Specifications

| TECHNICAL SPECIFICATION OF Z AND C | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| purlin DEPTH D | Thickness(t) | Mass(Kg/M) | Z PURLIN | C PURLIN | |||||

| F | L | F | L | ||||||

| 160 | 2.00 | 4.82 | 60 | 20 | 60 | 20 | |||

| 160 | 2.30 | 5.54 | 60 | 20 | 60 | 20 | |||

| 160 | 2.55 | 6.15 | 60 | 20 | 60 | 20 | |||

| 200 | 2.00 | 5.44 | 60 | 20 | 60 | 20 | |||

| 200 | 2.55 | 6.95 | 60 | 20 | 60 | 20 | |||

| 230 | 2.00 | 5.92 | 60 | 20 | 60 | 20 | |||

| 230 | 2.30 | 6.87 | 60 | 20 | 60 | 20 | |||

| 230 | 2.55 | 7.55 | 60 | 20 | 60 | 20 | |||

| 250 | 2.00 | 6.23 | 60 | 20 | 60 | 20 | |||

| 250 | 2.30 | 7.17 | 60 | 20 | 60 | 20 | |||

| 250 | 2.55 | 7.95 | 60 | 20 | 60 | 20 | |||

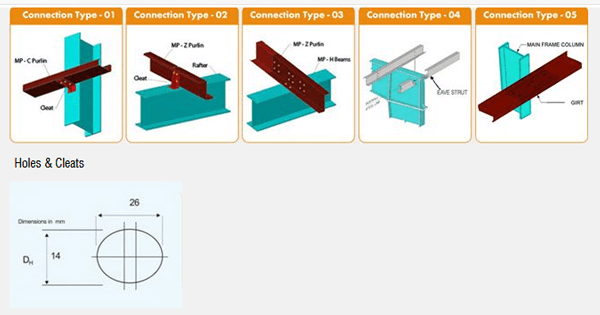

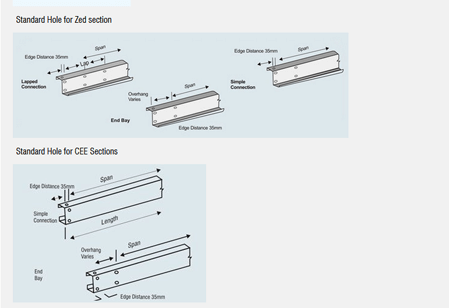

Typical Connection

- Purlin requires appropriate care during storage on site

- The period between delivery and installation to be minimized

- Purlin should be neatly stacked on the ground on a slight slope so that water can drain out

- On open site conditions, purlins should be protected with waterproof covers and condensation

- In case if the bundle of purlins becomes wet, separate the purlins and wipe & dry it

Applications

- Savings in steel consumption upto 50% and savings in cost upto 30%

- Savings of transportation & handling, erection and fabrication costs

- No wastages, No surplus left-overs, since sections are supplied in exact required lengths

- Sleeve system to exploit continuity concept for larger spans

- Empirical design rules apply, hence no design problems

- Excellent surface finish

- Less weight per unit length compared to conventional section without sacrificing the required structural efficiency

- Conforming to the requirements of IS-801, IS-811

Economy

Structure

- High strength, section versatility & wide range of choice

- Having their shear centre within the section, less liable to twist

Design

Advantages

- Ability to rotate 180 degrees and fit together

- A full range of fixing accessories is supplied. Therefore no extra material needs be procured

- Sections supplied are pre-painted hence prevents corrosion and promotes long life

- Sections are pre-engineered, pre-punched and with complete accessories. No further fabrication required . Considerable savings in erection costs and time.

Different Z&C purlin

- Yield Strength - 240 MPA

- Option - Redoxide Primer Coating

HR Purlins

- Coating Mass - 120 GSM / 180 GSM / 275 GSM

- Yield Strength - 240 MPA / 340 MPA / 550 MPA